Low Running Costs

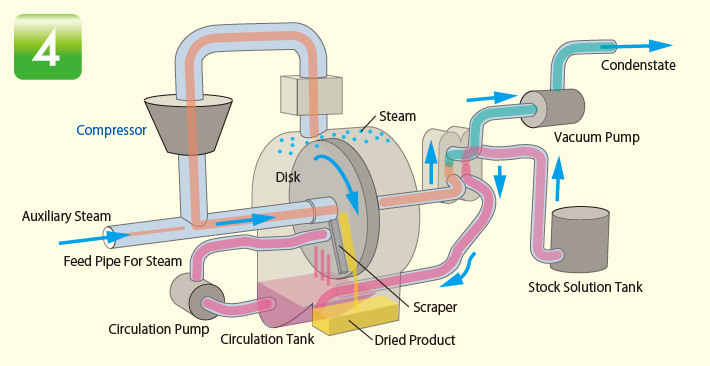

The H-VCD Dryer uses the same disk drying process as our regular CD Dryer, with the addition of an Okawara heat pump system, to save you on running costs. Steam generated in the drying process, normally released to the atmosphere by the CD Dryer, is compressed and recycled as a heat source for the disks. Energy consumption is reduced to just a fraction of that needed by a regular CD Dryer.

Flow of Operations

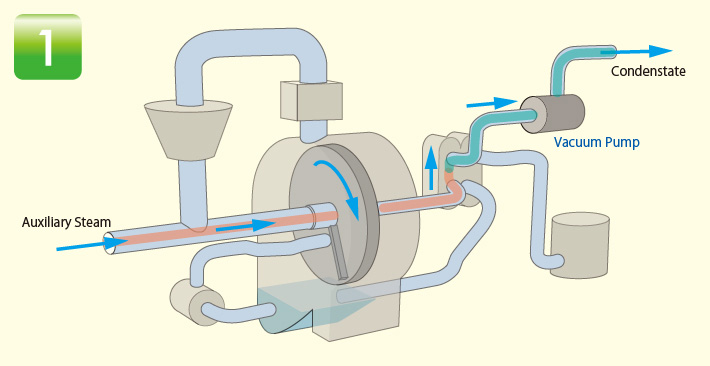

1. Auxiliary steam flows into disks, heating them from the inside. Condensed water from the disk drain passes through the heat exchanger and is expelled by the vacuum pump.

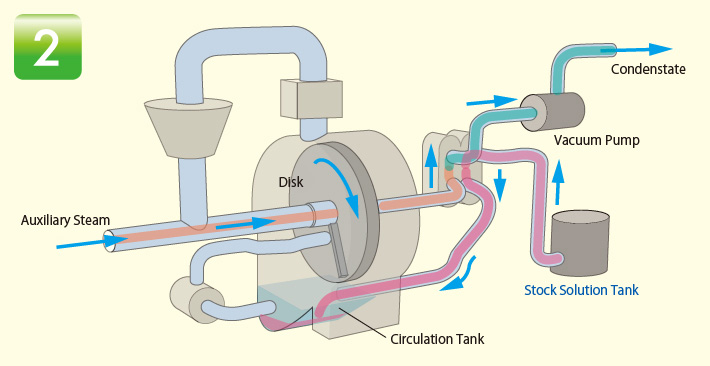

2. Stock solution, pre-heated by the heat exchanger, flows into the circulation tank inside the dryer.

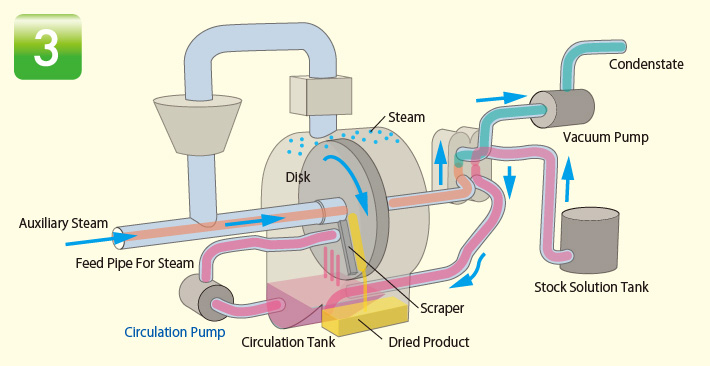

3. The circulation pump feeds solution onto the surface of the disks, where concentrating or drying occurs. Processed material is continuously scraped from the surface of the rotating disks.

4. Steam produced by the drying process is captured, compressed, and routed back as a heat source for the disks. Auxiliary steam consumption is therefore reduced, producing a huge savings in energy with this system.