RECOVER VALUABLE RESOURCES

Reduction of costs and your company’s ecological footprint, as well as supplemental income are some of the benefits you can expect when implementing a CD Dryer for recycling.

We especially recommend the CD Dryer as a tool for clients who produce or handle precious metals, rare metals, and pharmaceuticals.

MERITS OF USING A DRYER TO RECYCLE WASTE LIQUIDS

Often waste liquids contain substances that can be reused or recycled, but the difficulty of recovering these substances leads many companies to simply dispose of the liquid. Disposal itself costs money, and the loss of these valuable resources also affects your bottom line. Using a CD Dryer, your company can not only reduce its amount of waste liquid, but may be able to recover such recyclable or reusable materials.

| Recovery | Using the CD Dryer to recover resource materials, reuse or sale of the materials will add to your bottom line by reducing costs or bringing in supplemental income. |

|---|---|

| Reuse | By concentrating your diluted liquid, reuse or reintroduction to the production line may be possible, for example, with precious metals, rare metals and pharmaceuticals. |

CASE STUDY ‐ RECYCLING

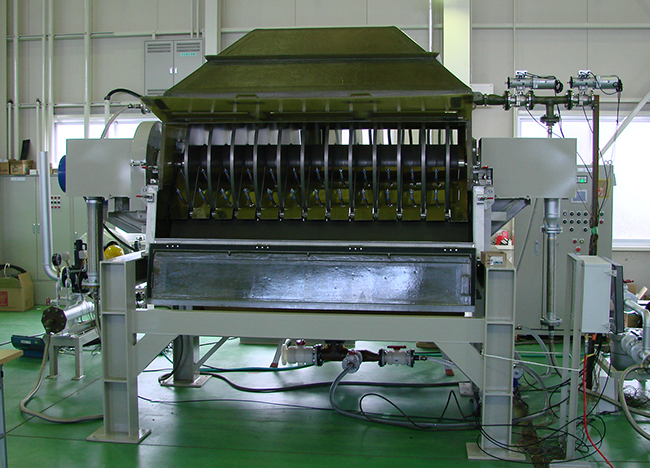

As a precious metal recovery company, Client Company B was spending about 90 million yen per year to dispose of its waste liquid. The introduction of 2 CD Dryers has led to a great reduction in those costs, and given the company a source of added income from sales of recovered resources.

INFORMATION

| Background Information | Client Company B, in the process of recovering precious metals, was producing about 10 tons of copper nitrate-containing wastewater per day. This wastewater (wet base 84%) was dewatered by pressing, leaving copper nitrate with an approximately 60% water content. This copper nitrate was then disposed of as industrial waste. |

|---|---|

| Client Needs | The client was looking for a way to make their copper nitrate remains fit for sale. |

RESULTS AFTER INTRODUCTION OF CD DRYERS

| Using a Press | Using CD Dryers | |

|---|---|---|

| Dried Material Water Content (84%Wet Base start) |

60%(-24%) | 20%(-64%) |

| Running & Disposal Costs (per year) |

90 million JPY (about $750,000 USD or €670,000*) |

30 million JPY (about $250,000 USD or €223,000*) |

| Other Merits | - | ・5 million JPY per year in sales (about $42,000 USD or €37,000*) ・Zero Emission Achieved |

(*based on an exchange rate of 1USD=120JPY, 1€=135JPY)

Using CD Dryers, the client is able to produce copper nitrate with a 20% water content. This powdered copper nitrate is sold to a mining company, where it is further processed to recover the copper. After introduction of the CD Dryers, the client was able to turn former waste into a valuable resource, which generates an income of 5 million JPY (about $42,000USD or €37,000*) per year, and in the process, was able to achieve zero emission at their plant.

WHAT IS ZERO EMISSION?

The concept behind Zero Emission in manufacturing is the recycle of all waste produced. This includes not only resource materials, but waste products and the greenhouse gases produced in power generation.