INTRODUCTION TO DRYERS

~THE CD DRYER ~

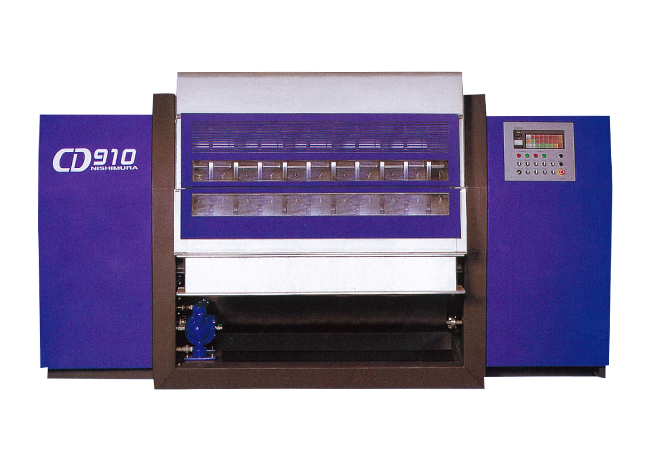

THE UNIQUE NISHIMURA CD DRYER UTILIZES DISKS AS ITS DRYING MEDIA

First and foremost, our customers choose Nishimura Works’ CD Dryers for their ability to get the job done. Using our unique technology, Nishimura Works has designed an energy-efficient, low-cost, process-reducing, space-saving, high-performance liquid dryer.

Compared to similar type dryers, such as drum dryers, the CD Dryer delivers an average TWICE the drying capacity per square meter of drying surface while using much lower steam pressure. It dries liquids using both sides of its thin disks, providing the same drying surface area in as little as 40% of the floor space of a drum dryer, allowing better utilization of available space and eliminating additional building requirements.

The CD dryer dries liquids instantly to a powder, eliminating extra process steps such as concentrating and pulverizing, greatly improving work efficiency. The simple design of the CD Dryer makes clean-up and maintenance easy, saving you time and money.

If your company is looking for equipment to produce powders, recycle liquid materials, or to simply treat liquid waste, the CD Dryer is the answer to your needs.

Nishimura Works will recommend the appropriate CD Dryer after thoroughly evaluating your needs through customer interviews, on-site reviews and test drying of your sample liquid. We will also provide technical data from previous tests of similar liquids and resulting dried materials.

The unique Nishimura CD Dryer has been recognized by both domestic and overseas customers as a superior drying machine. Nishimura Works is proud to have delivered our CD dryers to customers in 11 countries. We hold 7 Japanese patents, 6 overseas trademarks, and 3 Japanese trademarks.

COMPARISON OF DRYERS

| Machine Type | CD Dryer | Drum Dryer | Spray Dryer | |

|---|---|---|---|---|

| Drying Method | Thermal Conduction | Thermal Conduction | Nebulization | |

| Operational Overview |

Liquid poured onto flat face of steam-heated disk. Water evaporates during one rotation of disk. Dried material is scraped from disk with knife-like scraper and collected. Excess liquid is re-poured over disk by pump. | Liquid applied to circumferential surface of steam-heated drum. Water evaporates during one rotation of drum. Dried material is scraped from drum with knife-like scraper and collected. Single and double drum types available. Methods of liquid application vary. | Liquid is sprayed into heated atmosphere, instantly drying. Dried material is collected by cyclone, bag filter, etc. | |

| Condition of Dried Material |

Dry or Concentrated | Dry or Concentrated | Dry | |

| Operational Method |

Continuous | Continuous | Continuous | |

| Heat Source | Saturated Steam | Saturated Steam | Electricity, Steam, Gaseous or Liquid Fuel, Effluent Gas, Exhaust Heat | |

| Pressure of Steam Used | 0.1-0.4MPa | 0.4-0.8MPa | --- | |

| Casing Material | SUS or FRP | SUS | SUS | |

| Heat Transfer Surface Material (Surface Treatment) | Thermal Spray Coating (Main Component: Tungsten Carbide WC) | Hard Chrome Plating (Main Component: Chrome) | --- | |

| Liquid Treatment Capacity | 50-100kg/㎡ h | 25-60kg/㎡ h | --- | |

| Steam Usage (Compared to Amount of Liquid Treated) | 1.0 to 1.3x Amount of liquid treated |

1.5 to 1.6 x Amount of liquid treated |

--- | |

| Drying Time | 3 to 60 s | 12 to 60 s | Instantaneous | |

| Floor Space | 1 | 2.5 x CD Dryer | 12 x CD Dryer(Dryer only, exclusive of Auxiliary Equipment ) | |

| Size | ◎ | ○ | ▲ | |

| Initial Costs | ◎ | ○ | ▲ | |

| Running Costs | ◎ | ○ | ▲ | |

| Maintenance Costs | ◎ | ○ | Unknown | |

| Simplicity of System | ◎ | ◎ | ▲ | |

| Ease of Cleaning | ◎ | ◎ | ▲ | |

| Maintenance | ◎ | ○ | ▲ | |

| Prevention of Contamination | ○ | ○ | ▲ to ○ | |

| Dispersion of Dried Materials | ○ | ▲ | ◎ | |

| Time Needed for Start-up | 5 min | 45 min | --- | |

| Time Needed for Shut-down |

10 min | 45 min | --- | |

| Consumables | Scraper | Scraper | Nozzle, Rotary Disk | |

| Scraper Adjustment | Simple, even on large machines | Difficult on large machines | --- | |

※Comparison of machines with similar capacities. ◎= Very Good ○=Good ▲=Satisfactory

CD Dryers VS. Drum Dryers

| Dryer Type | CD Dryer | Single Drum Dryer | Double Drum Dryer |

|---|---|---|---|

| Process Overview | Liquid is poured over disk by pump. Liquid which does not adhere to the disk is reapplied. Liquid levels in the circulation tank are controlled automatically by the level sensor. | Liquid application occurs when the drum rotates through the dip tank. The level sensor automatically controls the amount of liquid in the circulation tank. | Liquid is top fed between the two drums. Feed amount is controlled by the metering pump. |

| Notes | A D-Type dryer’s body is built with less than its full set of drying disks in anticipation of a future increase in drying needs. For example, an SCD-1312D10 Dryer has 10 disks in a 12-disk casing. When drying requirements change, addition of the other 2 disks is an easy way to increase production. | With dip feed type dryers, problems caused by sedimentation can occur in the dip tank when liquid becomes concentrated. | With top feed type dryers, leaking can occur because adjustment of the space between drums is difficult. Also, hard materials in the liquid may cause damage at the meeting point of the 2 drums. |

| Feeding for top fed dryers is often done by a metering pump. Changes in viscosity and/or concentration can cause leaking or under-feeding. |