- HOME

- CD Dryer Lineup

A-VCD Dryer / E-CD Dryer / H-VCD Dryer

We offer three specialized variations of the CD Dryer: the vacuum type A-VCD Dryer, the electrically heated E-CD Dryer, and the energy-saving H-VCD Dryer.

Lineup and Specifications

A-VCD Dryer

The A-VCD Dryer offers stable drying and concentration in its vacuum chamber. The boiling point of liquids can be lowered, making drying and concentrating possible between 60℃ and 170℃. We offer A-VCD dryers heated by steam, hot water and heat transfer fluid.

Characteristics

- Highly airtight casing.

- Disks designed for low and high temperature applications

- Stable drying and concentrating in its vacuum chamber

- Low temperature drying is made possible by lowering the boiling point in its reduced-pressure atmosphere. (Drying temperature range: 60 to 170℃)

- Continuous oxygen-free drying made possible by the introduction of nitrogen etc. into the chamber

- Like the standard CD Dryer, it is energy and space saving.

- Built to meet your specialized needs

E-CD Dryer

The electrically heated E-CD Dryer does not use steam as a heat source, which can significantly reduce CO2 emissions from plants. Like the standard CD Dryer, this product is high performance, as well as space and energy saving. We offer drying tests at our company site. Off-site rental of a test machine can be also arranged.

Characteristics

- Plug it in and it's ready to go.

- Easily transportable.

- Disk temperature can be freely adjusted from low to high temperatures.

- Its small size makes it a great choice for making test samples or for low-volume production

- Scraper material can be selected to meet your application requirements

- Optimized for companies and factories using clean energy or aiming for zero emission.

Test Dryer Specifications

※You can check the table by scrolling left and right.

| Model | Heat Transfer Surface | Disk Material | Scraper Material | Voltage | Heater Power | Dimensions |

|---|---|---|---|---|---|---|

| E-SCD-600 | 0.5m2 | SB410+WC | SUS420J2 | 200V | 21.6kW | W1390×D1200×H2220 |

H-VCD Dryer

This energy-saving model incorporates a heat pump system on the CD Dryer. The steam produced in the drying process is not released to the atmosphere but is compressed by the heat pump and reused as a heating source, thereby reducing energy consumption to a fraction. Evaporation tests with water have resulted in an approximately 85% reduction in steam consumption compared to the conventional CD Dryer, with a 6.5 COP (coefficient of performance) attained.

Characteristics

- The capture and reuse of waste heat by the heat pump reduces energy consumption to only a fraction of our standard CD Dryer.

- Running costs are dramatically lower than standard dryers.

- Powder dried on the heat transfer surface is removed by the scrapers.

- The use of both sides of the multiple disks as heat transfer surfaces is efficient for ensuring a large drying area in a compact footprint.

- This space-saver is easy to install

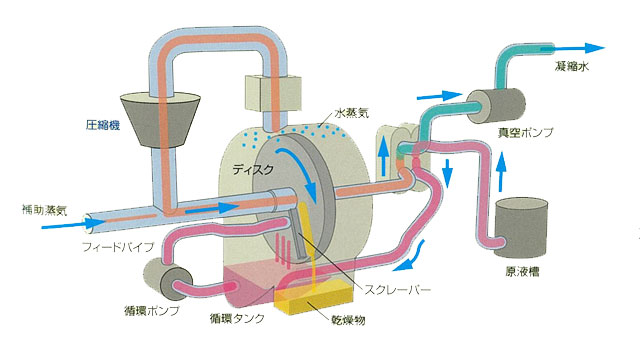

※The heat pump system compresses the generated water vapor and reuses it as a heating source.

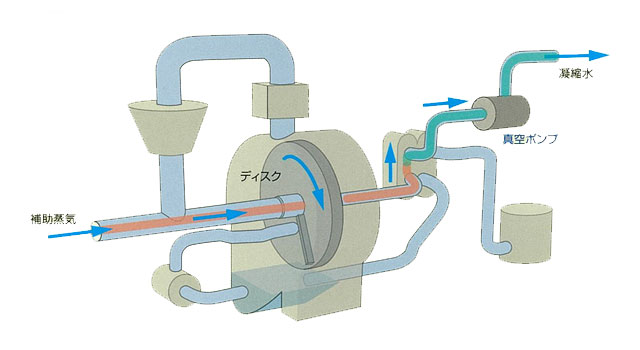

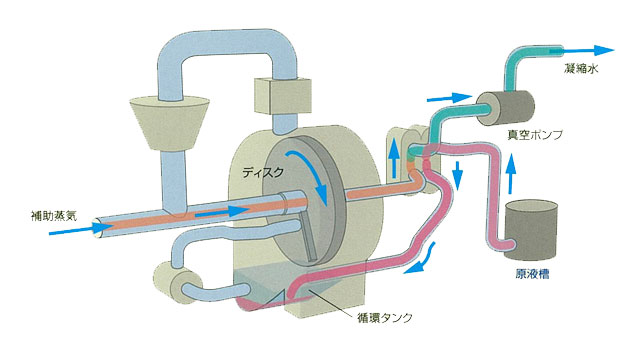

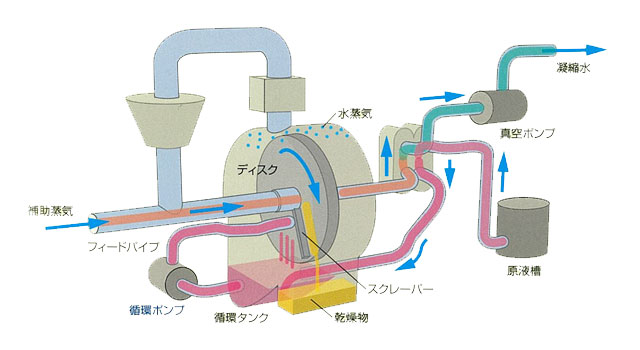

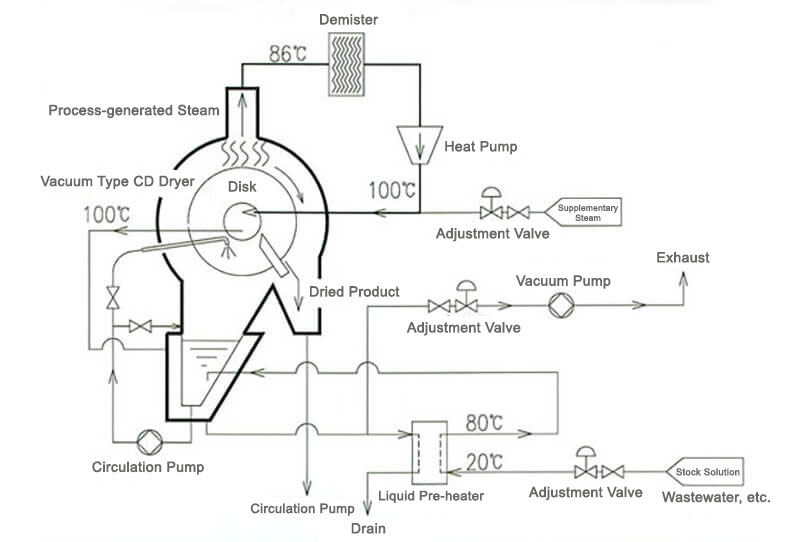

Flow Diagram

-

01Auxiliary steam is supplied to heat disks from the inside. Condensate passes through the heat exchanger, to preheat stock solution and is drained by the vacuum pump.

-

02Preheated stock solution is supplied to the circulation tank.

-

03Stock solution is fed onto the disk faces by the circulation pump, is concentrated and/or dried, and continuously removed by the scrapers.

-

04Steam generated by the drying process is compressed and fed to disks as a heat source. The usage of auxiliary steam decreases and new energy consumption is greatly reduced.

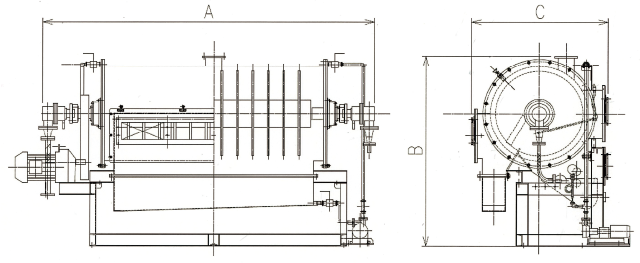

Main specifications

※You can check the table by scrolling left and right.

| Specification | H-VCD902 | H-VCD904 | H-VCD906 | H-VCD908 | H-VCD910 | H-VCD912 | |

|---|---|---|---|---|---|---|---|

| Disk diameter | 900 | ||||||

| Number of disks | 2 | 4 | 6 | 8 | 10 | 12 | |

| Heat transfer area (m²) | 2 | 4 | 6 | 8 | 10 | 12 | |

| Water evaporation capacity (kg/h) | 100 | 200 | 300 | 400 | 500 | 600 | |

| Utility | Steam consumption (kg/h) | 18 | 36 | 54 | 72 | 90 | 108 |

| Power kW | 15.1 | 21.4 | 27.4 | 32.9 | 45.1 | 46.6 | |

| Cooling water (L/min) | 13 | 15 | 17 | 20 | 20 | 30 | |

| Main Unit Dimensions (mm) | A | 1860 | 2180 | 2500 | 2820 | 3140 | 3460 |

| B | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 | |

| C | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | |

CD dryer special site

More detailed explanations and usage examples of Nishimura Works’ dryers can be found on the following page.