- HOME

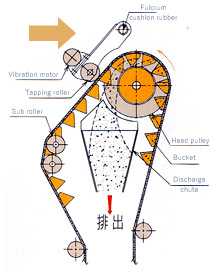

- I-B Conveyor

Internal Bucket Conveyor

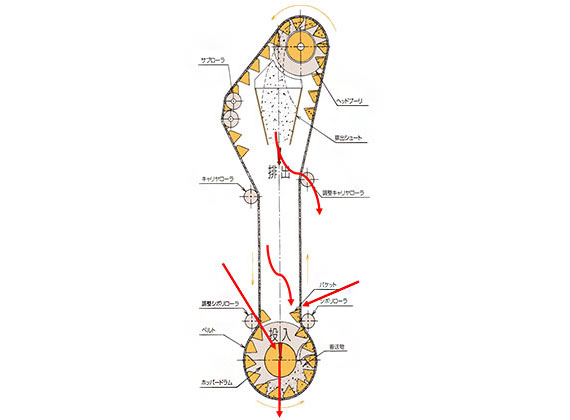

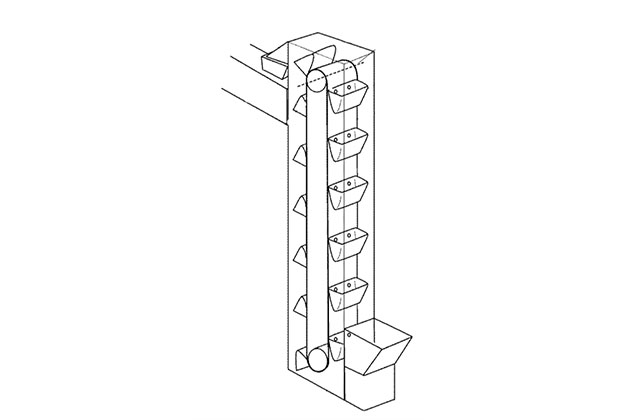

The Nishimura I-B Conveyor is an innovative internal bucket conveyor with features and advantages not available in conventional outer bucket conveyors, such as extremely smooth loading, natural discharge, and the optional use of rubber bucket materials to prevent sticking. Due to its structure, the impact to buckets during loading is extremely small, so buckets wear less and have longer service lives.

I-B Conveyor

- I-B stands for Internal Bucket. This vertical conveyor has its buckets attached to the inside of the belt.

- Liquids and granules can be transported vertically.

Reference

This I-B Conveyor has a belt width of 1200mm. It can transfer 180t/hour to the equivalent height of a nine-story building (26m.)

| Model Number | IB-120A26 |

|---|---|

| Belt width | 1,200㎜ |

| Shaft to Shaft Height | 26m |

| Power | 30kW |

| Belt speed | 40m/min |

| Transport volume 180t/h | 180t/h(133m³/h) |

| Transported material | Ferroalloys, slag-making materials |

| Applications | ||

|---|---|---|

| Granulated slag | Coke | Coal |

| Lime | Iron powder | Glass |

| Ferroalloy | Wooden pellets | Refractory materials |

| Ceramics | Silica stone and sand | Gypsum |

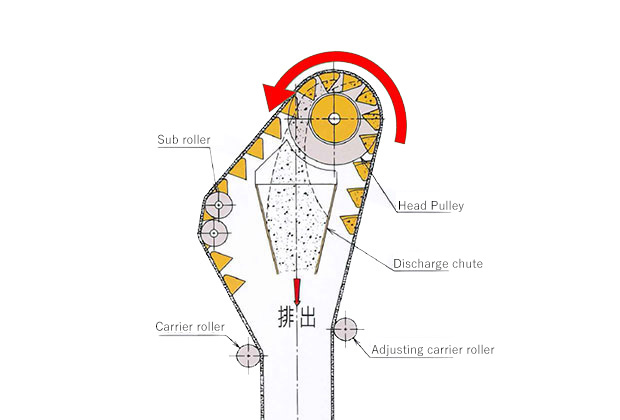

Structure

※You can check the table by scrolling left and right.

Loading

※You can check the table by scrolling left and right.

| Advantages of Smooth Loading | |

|---|---|

|

|

|

|

Discharge

| Merits of the I-B Conveyor | |

|---|---|

|

|

|

|

|

|

Where is the I-B Conveyor Used?

| Materials | Applications |

|---|---|

| Ferroalloy auxiliary materials |

Delivered to: Blast furnace manufacturers, electric furnace manufacturers All materials loaded are fully discharged, so that a single unit can carry a variety of materials without mixing. |

| Coal |

Delivered to: Steel manufacturers, power plants, and waste incinerator plants Optional rubber bucket material can be used to prevent adhesion. |

| Slag |

Delivered to: Waste incineration plants Gentle loading ensures a long service life, even for transport of highly abrasive materials |

| Casting sand, construction sand, crushed stone |

Delivered to: Ceramics manufacturers, quarries Materials roll into the bucket without being compressed, resulting in good separation and smooth discharge. |

| Dust from dust collectors, ferrite and other powders |

Delivered to: Steel Manufacturers A special hopper drum for powders enables automatic collection of suspended dust. |

| Food products and chemicals |

Delivered to: Food and chemical manufacturers Because of its sealed structure, dust is not generated outside the conveyor, so the I-B Conveyor can be incorporated into clean atmosphere lines. |

Differences Between I-B Conveyors and Outer Bucket Conveyors

| I-B Conveyor | Outer Bucket Conveyor | |

|---|---|---|

| Impact at loading |

|

|

| Bucket |

|

|

| Adherence |

|

|

| Tensioning device |

|

|

| Power |

|

|

| Capacity |

|

|

| Spill |

|

|

| Residuals |

|

|

| Bucket Detachment |

|

|

| Conveyor Play |

|

|

| Noise |

|

|

Specifications

Main specifications

※You can check the table by scrolling left and right.

| IB-25 | IB-35 | IB-45 | IB-60 | IB-75 | IB-90 | IB-105 | IB-120 | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Belt width (㎜) | 250 | 350 | 450 | 600 | 750 | 900 | 1,050 | 1,200 | ||

| Height (m) | 3~30 | 4~40 | 4~40 | 4~50 | 5~50 | 5~60 | 6~60 | 7~70 | ||

| Capacity m³/h |

Belt speed m/min |

20 | 4.2 | 6.9 | 10.2 | 21.1 | 31.5 | 56.7 | 69.3 | 83.9 |

| 25 | 5.2 | 8.7 | 12.8 | 26.4 | 39.4 | 70.8 | 86.7 | 104.9 | ||

| 30 | 6.2 | 10.4 | 15.3 | 31.7 | 47.3 | 85 | 104 | 125.9 | ||

| 35 | 7.3 | 12.2 | 17.9 | 37 | 55.2 | 99.2 | 121.4 | 146.9 | ||

| 40 | 8.4 | 13.9 | 20.5 | 42.3 | 63.1 | 113.4 | 138.7 | 167.9 | ||

| Maximum particle size (mm) | 20 | 30 | 50 | 70 | 100 | 150 | 200 | 250 | ||

| Loading and discharge chute opening (mm) | □200 | □250 | □300 | □400 | □450 | □500 | □550 | □600 | ||

Machine height is the distance between the axles of the upper and lower pulleys. Designate in units of 10 mm.

Capacity is based on a bucket loading rate of 70%.

A pass-through belt conveyor can be substituted for the discharge chute,.

If the conveyed volume is small, the maximum allowable piece size may be adjusted upward. Contact us for details.

Conveyors are custom designed and manufactured according to customer requirements.

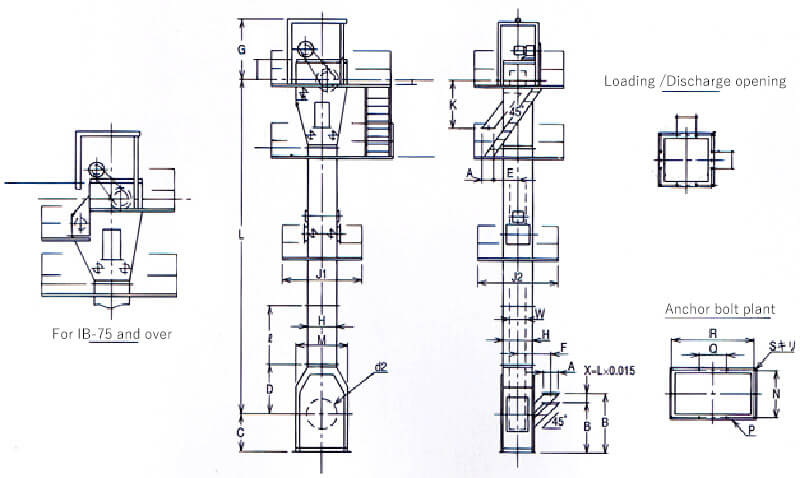

EXTERNAL DIMENSIONS

Standard Dimension Table

※You can check the table by scrolling left and right.

| IB-25 | IB-35 | IB-45 | IB-60 | IB-75 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W | 250 | 350 | 450 | 600 | 750 | |||||

| A | □200 | □250 | □300 | □400 | □450 | |||||

| H×H | □450 | □530 | □630 | □800 | □1000 | |||||

| L (m) |

3~15 | 15~25 | 4~15 | 15~25 | 4~15 | 15~25 | 4~15 | 15~25 | 5~15 | 15~25 |

| B | 1020 | 1170 | 1140 | 1290 | 1270 | 1420 | 1500 | 1650 | 1730 | 1880 |

| C | 650 | 800 | 700 | 850 | 750 | 900 | 900 | 1050 | 1050 | 1200 |

| D | 1150 | 1300 | 1300 | 1450 | 1400 | 1550 | 1600 | 1750 | 1900 | 2050 |

| E | 380 | 450 | 500 | 600 | 700 | |||||

| F | 450 | 530 | 630 | 750 | 900 | |||||

| G | 1400 | 1700 | 1700 | 2000 | 2200 | |||||

| K | 770 | 920 | 1030 | 1290 | 1560 | |||||

| M | 950 | 1120 | 1110 | 1440 | 1740 | |||||

| N | 2×265 | 2×305 | 2×355 | 2×460 | 2×560 | |||||

| P | L75×75×9 | L75×75×9 | L75×75×9 | L100×100×10 | L100×100×10 | |||||

| Q | 330 | 400 | 430 | 520 | 2×465 | |||||

| R | 1030 | 1200 | 1290 | 1560 | 1850 | |||||

| S | 22 | 22 | 22 | 22 | 27 | |||||

| l | 2400 | 2400 | 2400 | 2400 | 2400 | |||||

| j1 | 1800 | 1900 | 2000 | 2200 | 2400 | |||||

| j2 | 1800 | 1900 | 2000 | 2200 | 2400 | |||||

※You can check the table by scrolling left and right.

| IB-90 | IB-105 | IB-120 | ||||

|---|---|---|---|---|---|---|

| W | 900 | 1050 | 1200 | |||

| A | □500 | □550 | □600 | |||

| H×H | □1200 | □1400 | □1500×1900 | |||

| L (m) |

5~15 | 15~25 | 6~15 | 15~25 | 8~15 | 15~25 |

| B | 1950 | 2100 | 2130 | 2280 | 2630 | 2780 |

| C | 1200 | 1350 | 1300 | 1450 | 1650 | 1800 |

| D | 2250 | 2400 | 2650 | 2800 | 3350 | 3500 |

| E | 825 | 950 | 1100 | |||

| F | 1050 | 1200 | 1400 | |||

| G | 2400 | 2600 | 2800 | |||

| K | 1780 | 2180 | 2360 | |||

| M | 2060 | 2300 | 3400 | |||

| N | 2×660 | 2×770 | 2×700=2100 | |||

| P | L100×100×10 | L130×130×12 | t12 | |||

| Q | 2×545 | 2×610 | 3×720 | |||

| R | 2180 | 2440 | 3600 | |||

| S | 27 | 27 | 35 | |||

| l | 2400 | 2400 | 5000 | |||

| j1 | 2600 | 2900 | 3600 | |||

| j2 | 2600 | 2900 | 3200 | |||

Contact us about upper deck dimensions and for dimensions of conveyors 25m or higher.

Dimensions B and K are based on standard chute angles of 45°. The chute angle can be changed based on customer needs.

For connection of the inlet, plan for an additional stretching allowance of 200mm at B.

Subject to change for improvement.

Optional Equipment

※You can check the table by scrolling left and right.

I-B Conveyor Case Studies

Click here to learn more about I-B Conveyor applications.