- HOME

- CD Dryer

Compact Disk Dryer

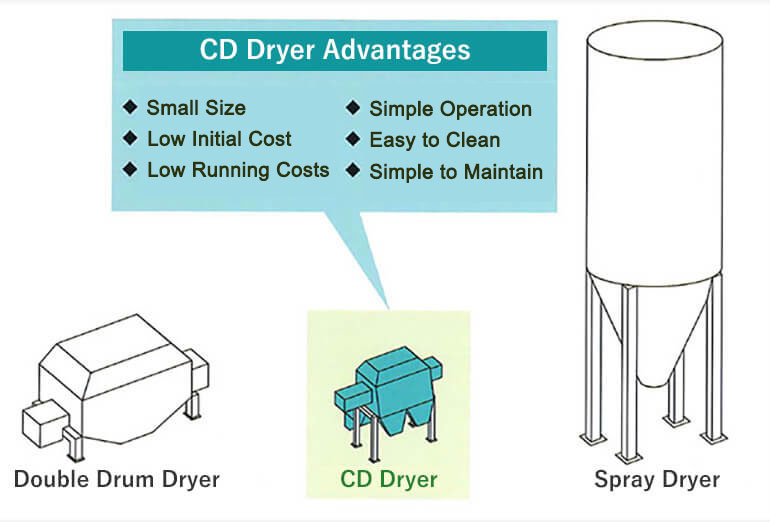

Nishimura Works' signature product, the CD Dryer (Compact Disk Dryer) is an indirectly-heated contact dryer for liquids. Learn more about the features, benefits, and specifications of the CD Dryer and about specialty CD Dryer models such as the vacuum type A-VCD Dryer, the electrically heated E-CD Dryer, and the H-VCD Dryer, an energy-saving model with a heat pump system.

Features of CD dryer

| High Performance & High Efficiency |

|

|---|---|

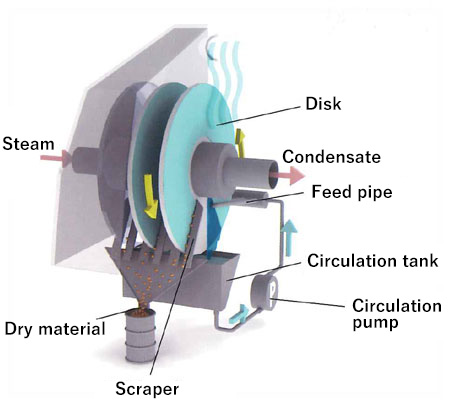

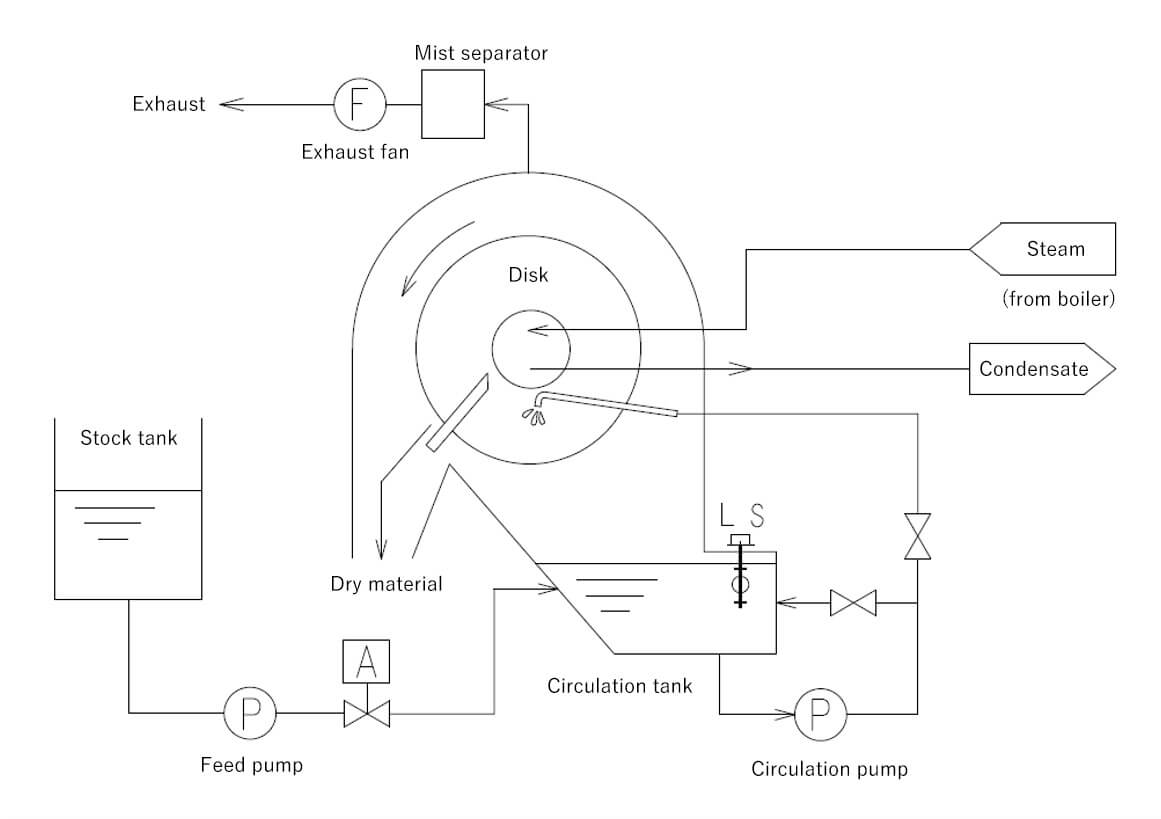

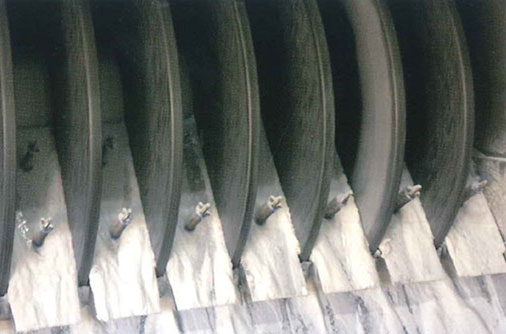

| How the CD Dryer Works | Three disk model shown

|

Standard Flow Sheet

Liquid is Supplied to Disk Surfaces

Stock solution from the circulation tank is pumped onto the disks through the feed pipes. The liquid spreads into a thin film, improving heat transfer. Excess solution falls back into the circulation tank to be re-fed.

Drying

Solution which adheres to the heated disk surfaces is dried as the disks rotate. By changing the disk rotation speed and steam pressure (drying temperature), it is possible to adjust the processing capacity and water content of the dried product.

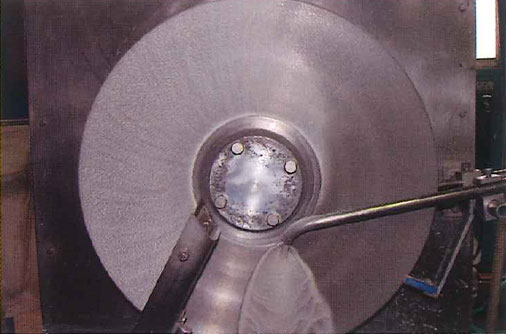

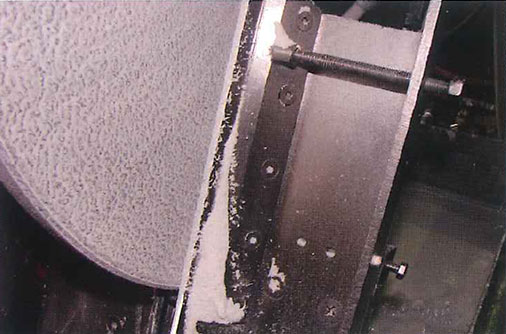

Collection of Dry Material

Scrapers remove product from the disk surfaces. The disks (heat transfer surfaces) are continually cleared by the scrapers to maintain good heat transmissibility.

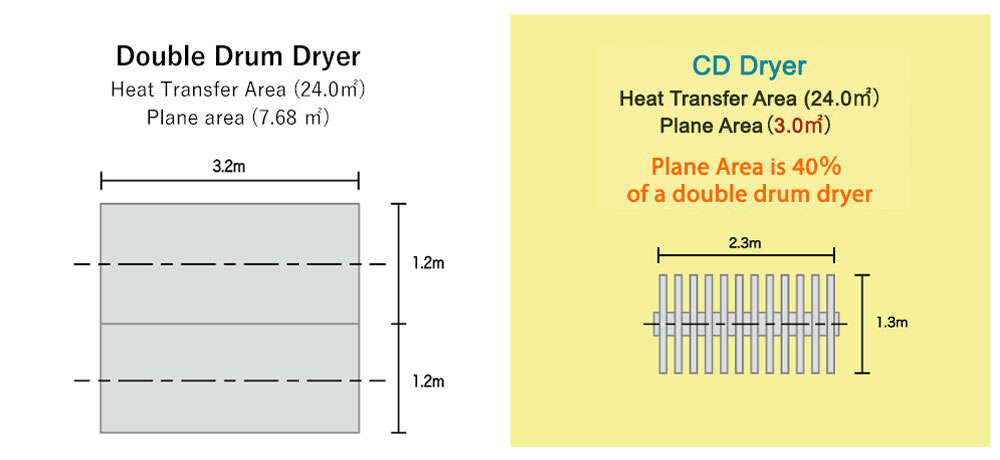

Compact size

The space-saving footprint of CD Dryer is about 40% that of a double-drum dryer with the same heat transfer area.

Comparison of Dryers

CD Dryer is distinctive in many other respects.

- Compatible with a wide range of applications, including powder production, drying/concentrating of waste liquids and recycling

- Save space and reduce installation costs by using one unit to both dry and powder all types of liquids, organic or inorganic

- Dry waste liquids to reduce volume

- Sell and make a profit from recovered resources such as precious or rare metals

- Protect the global environment while reducing corporate costs

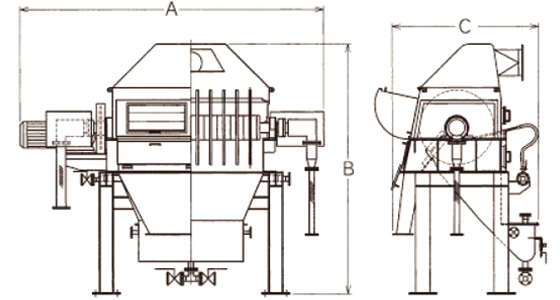

Specifications

Model

※You can check the table by scrolling left and right.

| Model | CD-500 | CD-903 | CD-906 | CD-908 | CD-910 | CD-912 | CD-1306 | CD-1308 | CD-1310 | CD-1312 | CD-1316 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Disk Diameter (mm) | 540 | 900 | 1,300 | |||||||||

| Number Of Disks | 1 | 1~12 | 6~16 | |||||||||

| Heat Transfer Area (m²) per disk |

0.4 | 1 | 2 | |||||||||

| Total Heat Transfer Area (m²) | 0.4 | 1~12 | 12~32 | |||||||||

| Dimensions mm | A | 1,390 | 2,070 | 2,690 | 3,070 | 3,490 | 3,940 | 3,680 | 4,130 | 4,580 | 4,980 | 5,780 |

| B | 2,180 | 2,440 | 2,940 | 2,940 | 2,940 | 2,940 | 4,700 | 4,700 | 4,700 | 4,700 | 4,700 | |

| C | 1,820 | 1,770 | 1,770 | 1,770 | 1,770 | 1,770 | 2,250 | 2,250 | 2,250 | 2,250 | 2,250 | |

Applications

※You can check the table by scrolling left and right.

| Water Content (%WB) | Steam Pressure (MPa) |

Liquid Processing Capacity (kg/m²h) |

Amount of Dried Product (kg/m²h) |

|||

|---|---|---|---|---|---|---|

| Original Liquid | Dried Product | |||||

| Ceramics | 67 | 0.2 | 0.3 | 100 | 33 |  |

| Ferrite | 60 | 0.1 | 0.3 | 175 | 70 |  |

| Pigment | 70 | 3.0 | 0.1 | 54 | 17 |  |

| Beer Yeast | 88 | 5.0 | 0.3 | 80 | 10 |  |

| Liquid Distillation Residue | 91 | 11.0 | 0.3 | 60 | 6 |  |

| Milk Beverage (Waste) | 89 | 1.2 | 0.15 | 29 | 3 |  |

| Water-based Paint Waste water | 98 | 10.0 | 0.13 | 63 | 1 |  |

| Resist (Waste) | 88 | 4.0 | 0.25 | 36 | 5 |  |

| Concentrated Salt Water | 80 | 10.0 | 0.25 | 48 | 11 |  |

| Waste solution containing Oil | 88 | 17.0 | 0.3 | 52 | 8 |  |

※You can check the table by scrolling left and right.

| Plating Waste |

Processed Food |

|---|---|

|

|

|

|

Applications of the CD Dryer

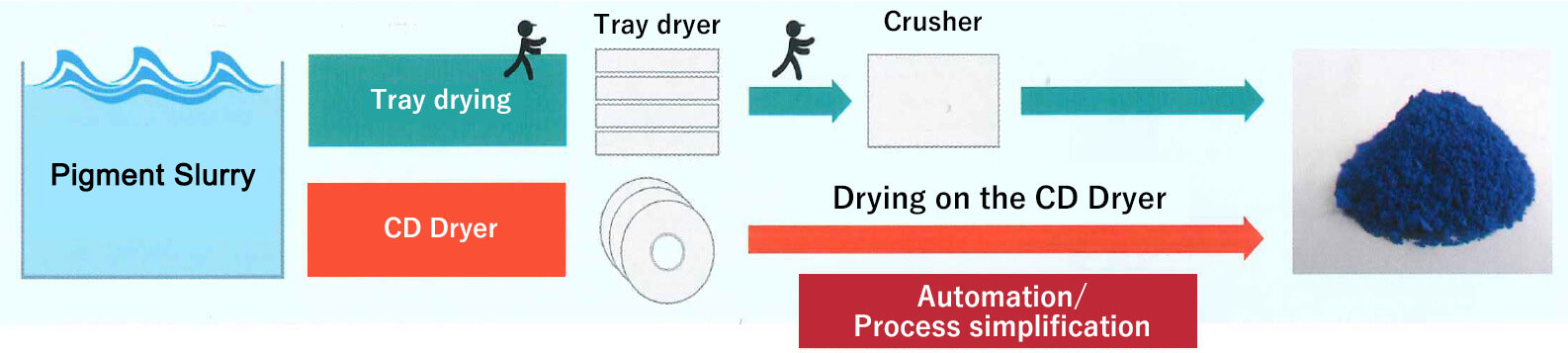

Production (Pigment)

The process was labor-intensive with poor working conditions and included manual steps. Using the CD Dryer, the process was automated and simplified, resulting in an improved working environment.

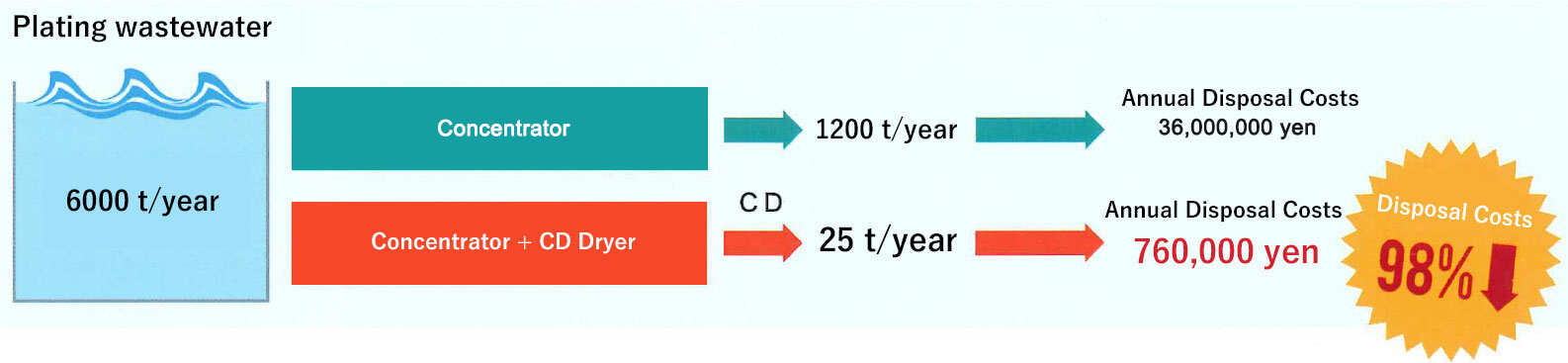

Wastewater Disposal

Every year, it cost about 36 million yen to treat 1200 tons of concentrated industrial waste. After introduction of the CD Dryer, the customer is able to dry the volume to about 25 tons, reducing emissions and the cost of industrial waste disposal to about 760,000 yen.

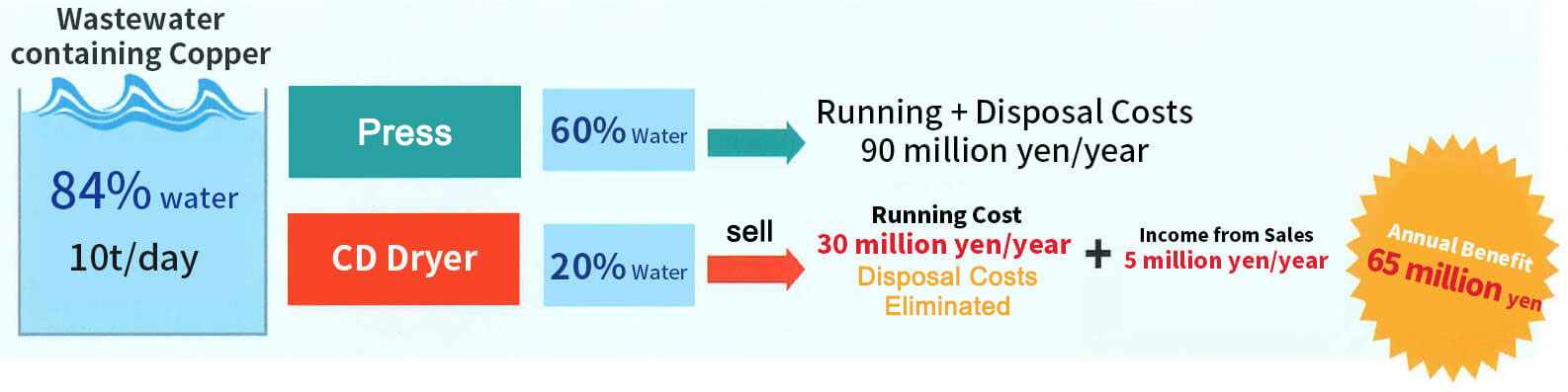

Recovery of Resources

Approximately 10 tons of wastewater containing a copper compound was discharged per day, and the cost of waste disposal was approximately 90 million yen per year. After the introduction of CD Dryers, however, the dried copper compound could be sold, resulting in a benefit of approximately 65 million yen per year.

Lineup and Specifications

Three specialized variations of the CD Dryer technology are also available. The A-VCD Dryer dries liquids under vacuum; the E-CD Dryer is electrically heated; and the H-VCD Dryer is an energy saving model equipped with a heat pump system.

A-VCD Dryer

The A-VCD Dryer offers stable drying and concentration in a vacuum environment. The boiling point can be lowered in its reduced pressure chamber, making drying and concentrating possible between 60℃ and 170℃.

E-CD Dryer

The electrically heated E-CD Dryer does not use steam as a heat source, eliminating CO2 emissions from steam boilers. Like the CD Dryer, this product is high performance, as well as space- and energy-saving.

H-VCD Dryer

This energy-saving model includes a heat pump system for the CD Dryer. The steam produced in the drying process is not released to the atmosphere but is compressed by the heat pump and reused as a heating source, thereby reducing energy consumption to a fraction.

CD Dryer Web Site

More detailed explanations and usage examples of Nishimura Works dryers can be found on the following page.